Laser cutting

Laser cutting is a precise method of cutting a design from a given material using a CAD file to guide it. There are three main types of lasers used in the industry: CO2 lasers Nd and Nd-YAG. We use CO 2 machines. This involves firing a laser which cuts by melting, burning or vaporizing your material. You can achieve a really fine level of cutting detail on with a wide variety of materials. Bare in mind that CO 2 lasers can’t cut metals and hard materials, they can however engrave them.

Die-cutting

Die cutting is a manufacturing process used to generate large numbers of the same shape from a material such as wood, plastic, metal, or fabric. The die cut shapes are sometimes called “blanks,” because they are usually finished and decorated before being sold. The process is widely used on an assortment of materials all over the world, and many manufactured products contain several die cut components, often assembled together in a series of steps to create a finished product.

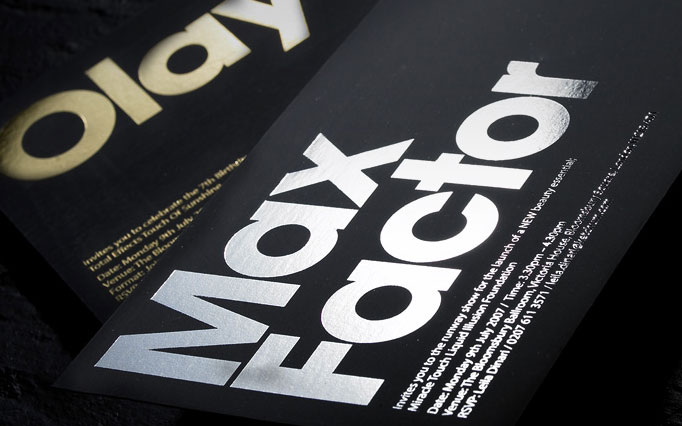

Foiling

Foil stamping is a special kind of printing procedure where heat, pressure, and a metallic paper (foil) is used to create different shiny designs and graphics on various materials. Foil stamping gives the stamped design a shiny and incredible look and is increasingly becoming the preferred method of printing in many an industry.

Foil stamping is also referred to as hot stamping (because of the use of heat), foil printing, dry stamping, and leaf stamping. There are various types of foil stamping that can be used depending on your design needs.

Varnishing

Fine varnish can be sprayed on to the surface of card. When dry this gives a gloss finish and helps protect the printing underneath. The printing and colour work must be completed before this process takes place. Also, folding a package takes place after the varnish has been applied.

Different types of varnish are available. The most popular are oil and water based varnishes. In either case, the varnish takes at least two hours to dry. This may be a disadvantage especially if the card is being used for a package - as it means it can not be folded straight away.

UV-varnishing

Special varnishes dry almost straight away if they are exposed to ultra violet light. (UV light). The varnish is sprayed on to the paper / card in the same way as other varnishes. However, after spraying the card passes underneath UV lights which dries the varnish almost instantaneously.

One disadvantage is that this type of machinery is expensive to purchase. However, it produces an excellent gloss finish to the card / paper.

Spot-varnishing

A special effect that puts an overprint varnish only on specific areas of a printed piece, spot varnish is often used to make a photograph pop off the page, highlight drop caps, or to create texture and subtle images on the page.

Embossing

Embossing refers to the creation of an impression of some kind of design, decoration, lettering or pattern on another surface like paper, cloth, metal and even leather, to make a relief. In regular printing or an engraving, plates are pressed against the surface to leave an imprint. In embossing however, the pressing raises the surfaces adding a new dimension to the object.

Lamination

Lamination is a process of protecting documents through applying film of plastic on documents. It is a good way of protecting documents from damage and also from wear and tear. Laminated documents are waterproof and tear proof.

Debossing

There are several debossing techniques. A blind deboss is used with screen-printing or foil stamping. With the screen process, the art or design is first printed onto the material and then the outline of the print is debossed using a die exactly registered to the silk screen print. In foil stamping, the foil is transferred to the material using a special die and then the same die is used to deboss the area. Debossing is less complicated than embossing, and when done in conjunction with silk screen printing, it results in a colourful and more detailed rendering of artwork and lettering.

No comments:

Post a Comment